Midnight mission

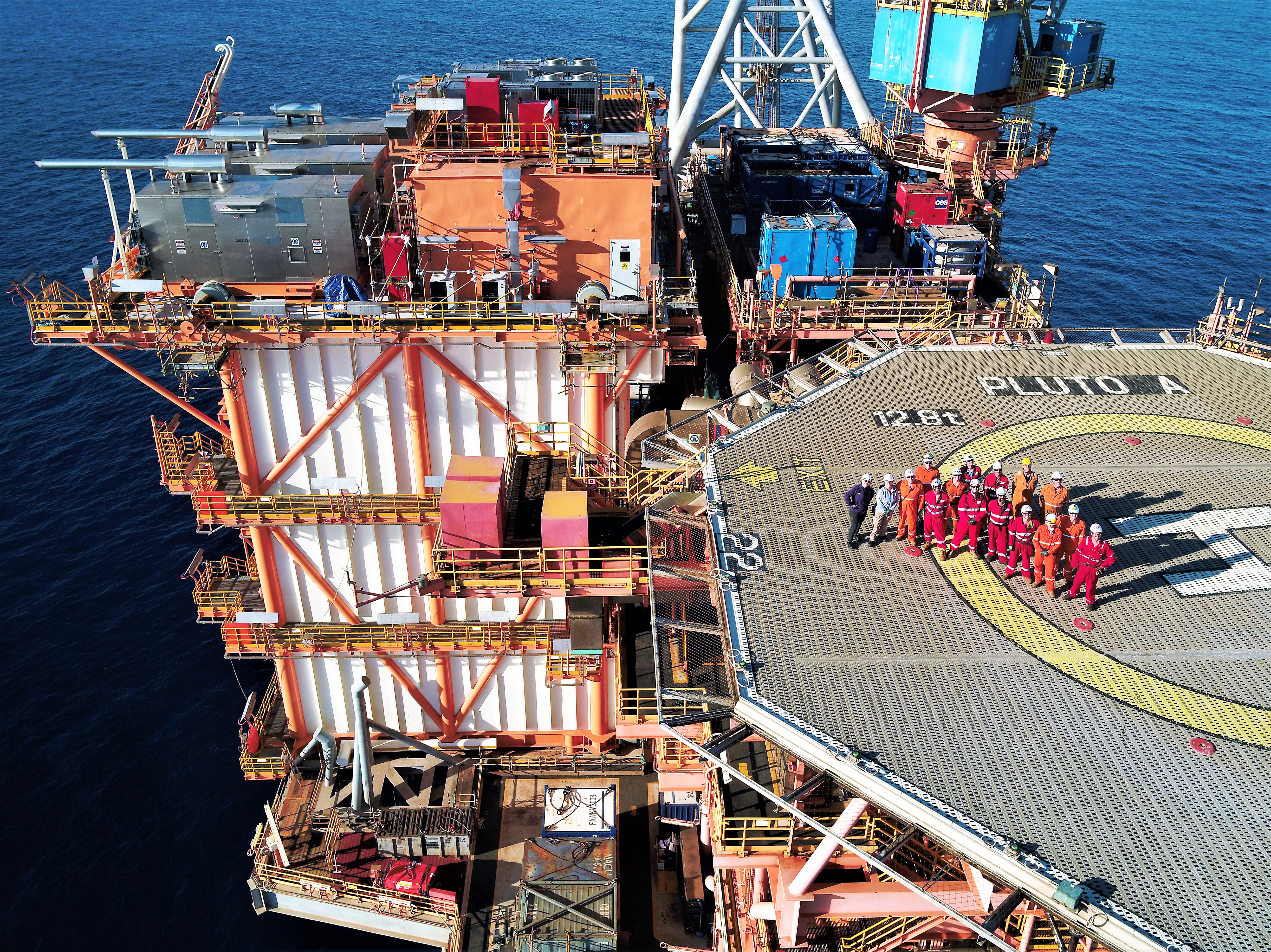

A massive water handling unit designed to manage “wet” gas has been safely delivered in the middle of a November night to Pluto Platform, off the coast of Western Australia.

As Pluto’s reservoirs mature, the gas extracted could comprise increasing amounts of water, as is the case with most hydrocarbon reservoirs. That proportion will soon require the services of a dedicated water handling unit to handle the “wet gas”.

One such unit was safely delivered in November – in the middle of the night when ocean conditions were considered optimal, and after simulations were conducted in The Netherlands. It took only three hours for the vessel carrying the unit to enter the 500m exclusion zone surrounding the Pluto platform (PLA), unload the module and then depart the exclusion zone; but it was the result of more than four years’ meticulous work.

“It’s a significant milestone in the life of Pluto LNG,” says Project Manager Andy Angus, who watched the procedure 1200 km away in the Pluto Remote Operations Centre at Mia Yellagonga, Perth.

“It was only possible thanks to the tremendous collaboration across Woodside – including Projects, Engineering, Subsea, Operations Readiness, Pluto Asset, Logistics, Contracting and Procurement and others – as well as with contractors.”

The platform, constructed in Malaysia, was scheduled to be delivered months earlier, but COVID-19 put paid to those plans.

Indeed, the pandemic created numerous challenges in finishing, testing and delivering the module. But each and every hurdle was overcome thanks to the creativity of the teams involved and their teamwork, Andy says.

“These events continued to highlight the resilience everyone has shown over an extended period to deliver the project to this stage,” he notes.

The end result is a complex hydrocarbon processing unit.

To illustrate its size, at 1700 tonnes it’s about half the size of the topside on PLA.

It will separate the oil and water, treat the water and return it to the sea.

Constant monitoring will ensure it meets strict environmental requirements. From the hydrocarbon stream it can separate and process up to 22,000 barrels of water a day.

Working with the vendor the Operations Readiness and Health and Safety personnel developed a new lifting tool to simplify the replacement of the filters, minimising the human factors impact (see Trunkline Q3 2019).

Due to increased demands, the module includes three new power generators which should improve reliability over the existing system. And because the main engine is gas driven, emissions will be lower than the previous diesel machines.

To date the project, delivered through the Integrated Projects Program (IPP), has spanned more than 1.7 million hours without an injury across the various work locations since concept definition work began in August 2016.

With the module now landed, the team is focused on the remaining scope including hook-up of the connecting piping spools, cabling, stairs and infill panels along with download and testing of the new control system and commissioning of the new electrical generation and distribution system.

Mike Price, Vice President Pluto, FPSOs (floating production storage and offloading facilities) and Wheatstone, congratulated all responsible for the water handling unit.

“There has been great collaborative work by multiple teams to achieve this major milestone in this important project to ensure we maximise gas recovery from the Pluto fields,” Mike notes.

Read the full Q4 2020 issue of Trunkline here.